Why Veneered Wood?

Veneered Wood Tiles & Panels are an environmental friendly building product with endless possibilities. The wood is used efficiently in the production of veneer, as modern production methods ensure that around 800-1000 m2 of veneer can be produced from 1 m3 of wood. With the demountable clips, the panels can be easily installed and be removed to have access to the plenum.

Characteristics

Application

The Veneered Wood Tiles and Panels are suitable for all building sectors: Corporate, Transport (airports, metro-, bus -, train stations), Retail, Leisure, Public spaces, Hospitality, Healthcare, Education or Residential.

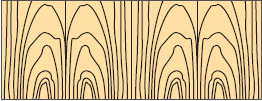

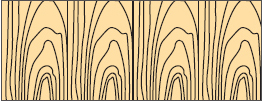

American Cherry

American Walnut

American White Oak

American Maple

Anigre

Ash

Bamboo

Beech

Birch

Cedar

European Oak

Hemlock

Koto

Pine

Red Oak

Spruce

Sycamore

Teak

.jpg)

.jpg)